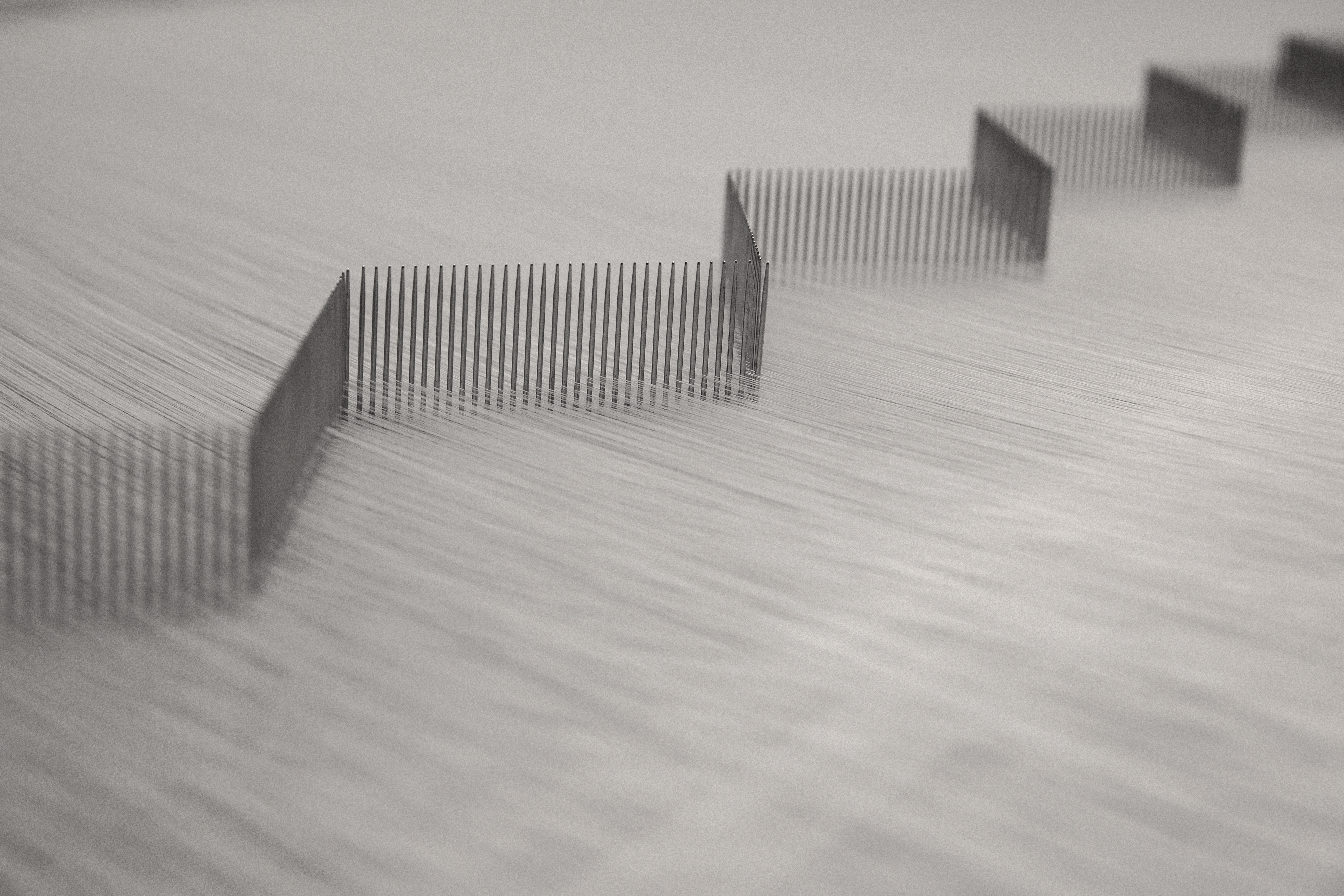

Our passion is to create new fabrics, to generate emotions never felt before.

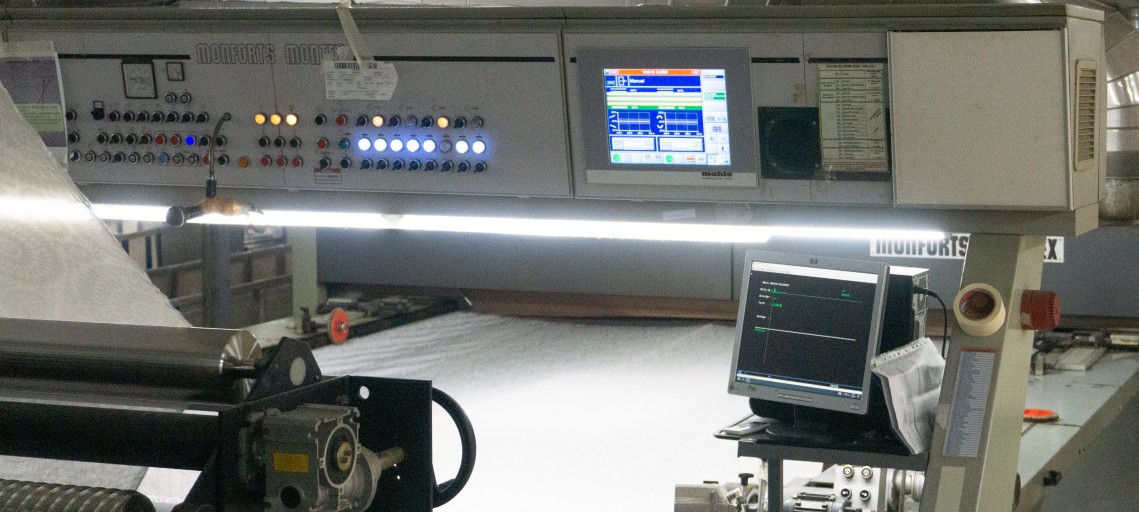

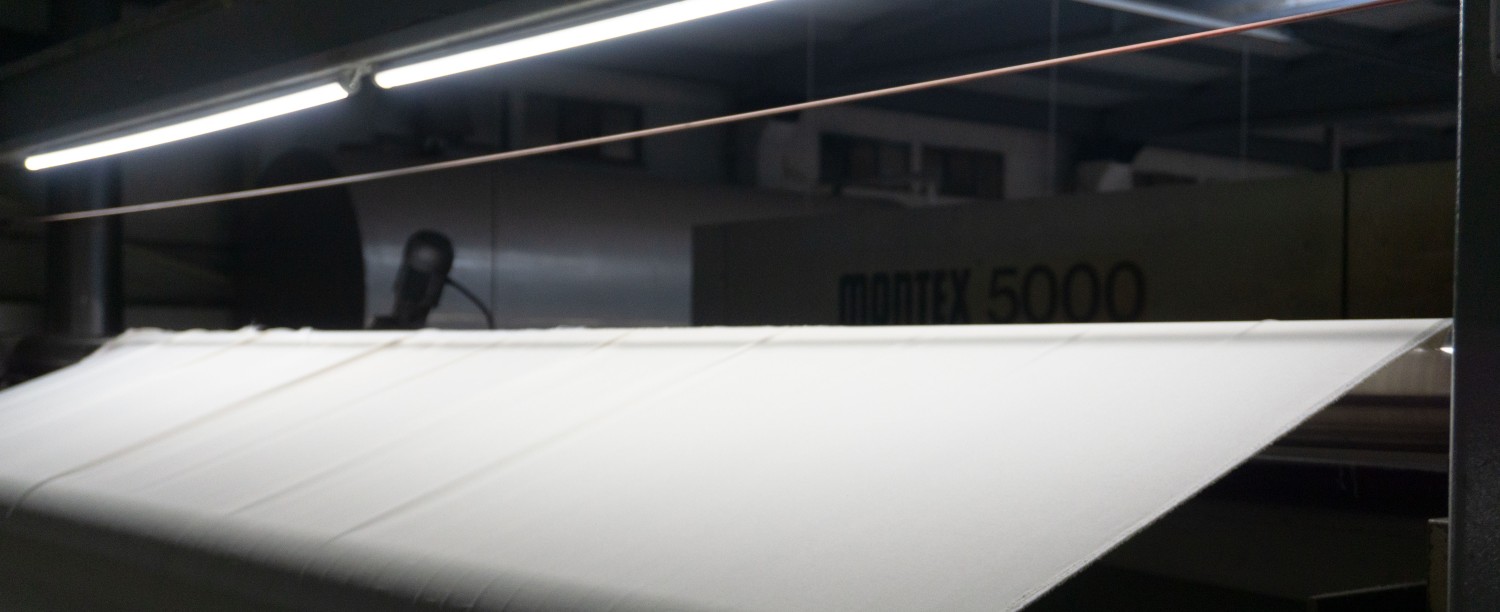

Our vertical production processes enable tailor-made manufacturing, increase resource efficiency, and enable total supply chain control. This all-encompassing approach is our guarantee of delivering the highest quality product.

Our expertise covers all processes - from yarn dyeing and preparation, weaving, piece dyeing, finishing, pleating, and digital and screen printing to readymade products. Our wide range of services allows us to offer a diverse range of products on a global scale – from residential living spaces to contract projects.

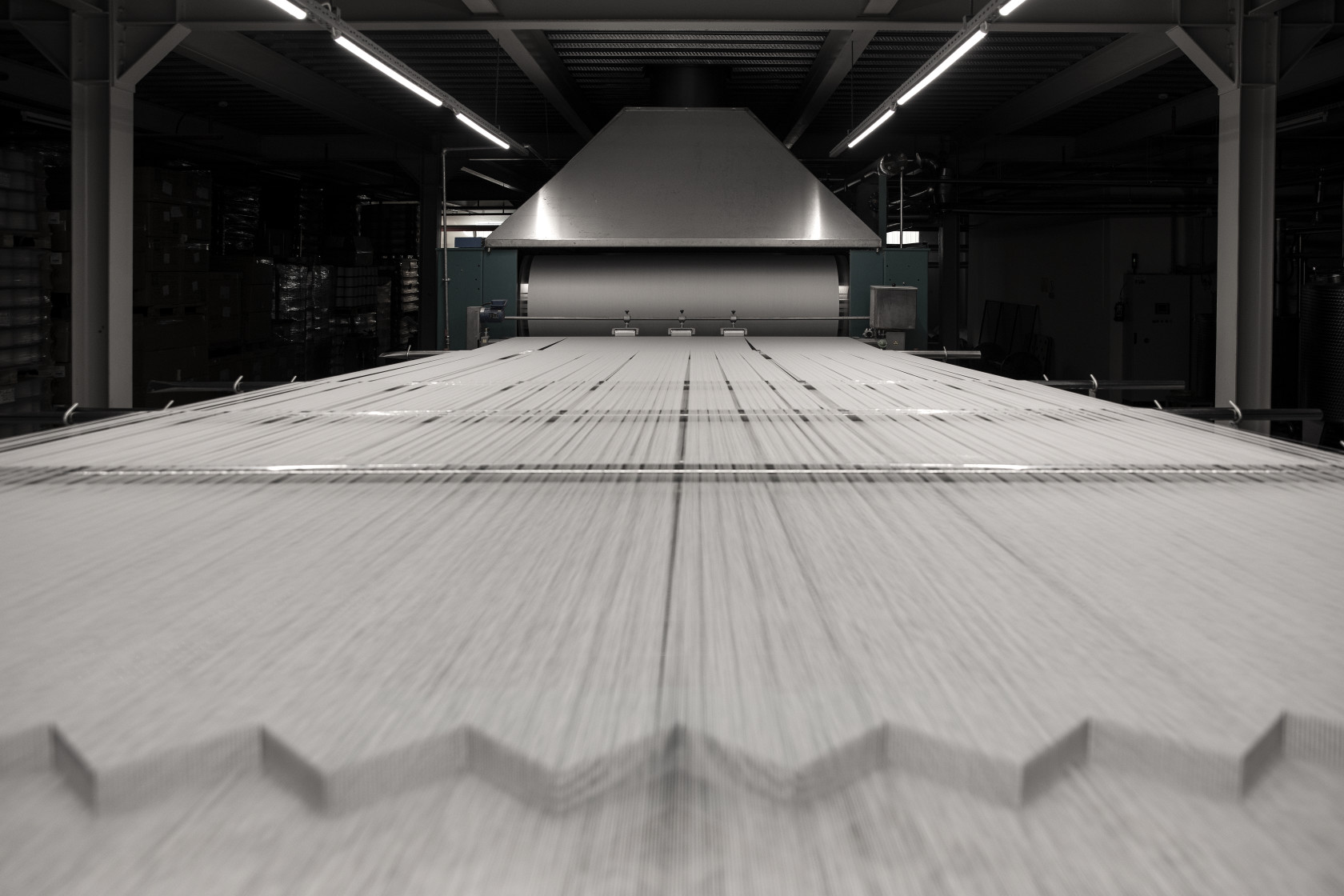

Thanks to the complete internalization of all processes within Vanelli, we have an integrated structure that works flawlessly from design to the final product and is subject to continuous development. At Vanelli, we use different technologies in three production lines - dobby and jacquard fabrics, relative dyes and finishes, and printed fabrics - which provide high quality and efficiency for that particular line.

With over 170 looms, we can produce large volumes faster, and simultaneously, we can manufacture small volumes giving life to our designs. This ability to adapt to external changes and demands grants us our unique edge and the ability to provide excellence and responsiveness in the market.

Because we’re flexible, we’ve made it our business to offer a range of modern, multi-faceted services and capabilities. Thereby making us appealing to editors, wholesalers, end-user clients, furniture designers and manufacturers alike.